East TN Ecosystem Connectivity

The East Tennessee ecosystem has unique and seamless integration across The University of Tennessee (UT), Oak Ridge National Laboratory (ORNL), Institute for Advanced Composites Manufacturing Innovation (IACMI), and over 150 small, medium, and large-scale industry partners – both national and international. The ecosystem is rich in entrepreneurship with mechanisms such as Innovation Crossroads paving the path for R&D leading to commercialization.

East TN ecosystem in Advanced Materials & Manufacturing technologies spans from:

- Basic to Applied Sciences

- The R&D spans Lab Scale to Intermediate Scale to Prototype

- Small Scale to Commercialization

- Service And End of Life Technologies

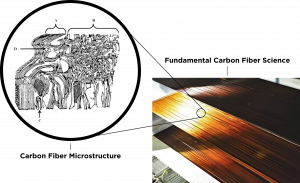

1. Fundamental Carbon Fiber Science at ORNL

ORNL has world-renowned R&D in the fundamental science of carbon fiber. Some of the recent efforts include-

- Low-cost textile-grade carbon fiber

- Custom melt spinning

- Activated carbon fiber

- PAN and pitch-based carbon fiber

- Carbon fiber precursor science

2. Carbon Fiber Technology Facility (CFTF) at ORNL

CFTF is the world’s largest pilot-scale carbon fiber R&D facility with 25 metric tons per year capacity. Flexibility to evaluate precursors, processing, sizing, packaging, and intermediates. The CFTF has pioneered low-cost textile-grade carbon fiber with 300-600k tow count.

Carbon Fiber Technology Facility

For more information – visit https://www.ornl.gov/facility/cftf

3. The University of Tennessee, Knoxville (UT)

UT is a flagship university in Tennessee with over 38,000 students. Several synergistic facilities make up UT’s advanced materials and manufacturing portfolio. About 40 graduate and ~100 undergraduate students work in advanced materials and manufacturing (composites, metals, additive manufacturing, etc.) any given semester. The students range from various disciplines such as – Mechanical, Materials, Civil, Nuclear, Chemical, Biomedical, Aerospace, Agricultural, Bio-resources Engineering, Physics, Chemistry, Architecture, and Health Care to name a few.

- Fibers and Composites Manufacturing Facility (FCMF) (IACMI-UT)

- Joint Institute for Advanced Materials (JIAM)

- Mechanical Characterization Facility

- Center for Renewable Carbon (CRC)

4. Manufacturing Demonstration Facility (MDF) at ORNL

MDF at ORNL is the world’s largest facility for comprehensive large and small-scale additive manufacturing, metrology, machine tools, advanced composites, recycling technologies, and holistic product development.

For more information, visit – https://www.ornl.gov/facility/mdf

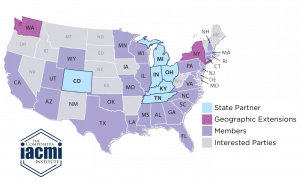

5. IACMI-The Composites Institute

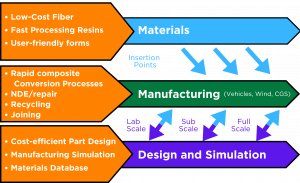

IACMI-The Composites Institute is a Manufacturing USA (MUSA) institute – unique in advanced composites, IACMI is headquartered in Knoxville and managed by Composite Collaborative Solution (CCS) with the University of Tennessee Research Foundation (UTRF). IACMI has key technology areas:

1) Tennessee – Materials & Processing Technologies

2) Indiana – Modeling & Simulation Technologies

3) Michigan – Vehicles Technologies

4) Colorado – Wind Technologies

5) Ohio – Aerospace and Gas Storage Technologies. IACMA has 140+ member partners and has executed `55 high-value industry-led technology projects.

IACMI has created a national network of composite assets and addresses projects at the Technology Readiness Level (TRL 4-7).

IACMI Partners Map

IACMI Technologies Range from TRL 4-7 & TRL 1-3