Filter media are currently used for HVAC systems, face masks, vacuums, and a variety of other applications. However, filter media are a substantial contributor to plastic pollution and there is a growing need for a sustainable approach to the use of filter media. UT FCMF and collaborators have developed a class of biodegradable filter media with reduced pore size for enhanced filtration efficiency. These media feature tunable properties and can be optimized for a variety of application. By varying the degree of fibrillation and particle refinement, the media have achieved a Minimum Efficiency Reporting Value, MERV, of up to 13 (residential synthetic air filters have an average MERV rating of 11-13). These filtration media are versatile, easy to manufacture, and feature increased resistance to heat and/or fluid flow. This technology has applications in air and gas filtration systems, infection control products like face masks and sanitizing articles like hand wipes and wound dressings. The materials are 100% recyclable, maintains air flow efficiency, possess increased heat resistance and achieve MERV 8 – MERV 13.

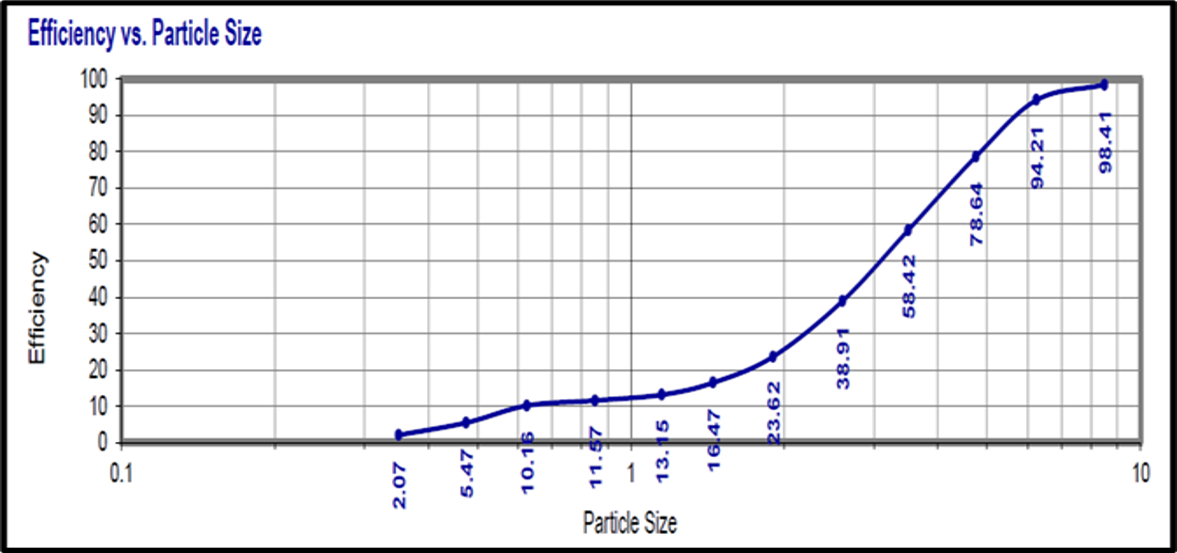

Representative performance of biodegradable filter media developed by the UT team