The following education resources have been made available to learn more about Fiber and Composites Manufacturing.

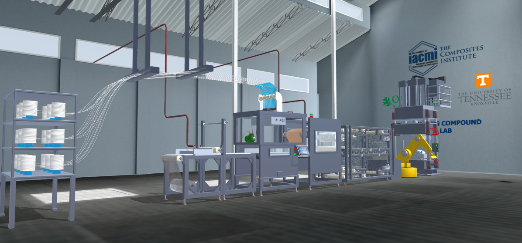

Virtual Reality (VR) Training in Composites Manufacturing

VR based Sheet Molding Compound (SMC) manufacturing training

Virtual reality (VR) technology involves the three-dimensional recreation of an environment via computer software, often experienced through a pair of goggles (headset) that cover the eyes. VR is rapidly growing in education. VR is adding a crucial element to the classroom: creating an immersive experience that allows students to learn by doing. The use of VR to educate students and workers for the composites industry is a unique feature of this chapter. VR modules can provide training and experience composites manufacturing in a realistic environment. Various composites manufacturing processes relevance to automotive, aerospace, transportation and sporting applications have been created in VR. The VR modules for fibers and composites education and training include, but are not limited to- (a) Carbon fiber production; (b) Sheet molding compound (SMC); (c) Extrusion Compression Molding; (d) Twin screw extrusion; (e) Thermoplastic long fiber production; (f) Pultrusion; (g) Roll forming; (h) Mold (tool) features; and (h) Injection molding. These processes are not only expensive, but every lab, company, or student may not have access to a high-end physical manufacturing environment. The VR content is viewable on Oculus Go and Oculus Quest, respectively. Conventional classroom content, videos, Powerpoint and VR provide the user holistic experience in composites materials and manufacturing.

ACE training in composites machining and machine tools

Workshops on Introduction to Composites, Composites Machining, Machine Tools, Product Development, Composites Processes and areas of related interest are conducted on quarterly basis. Workshop calendar is updated frequently. An example workshop conducted in Summer 2020 is provided in this link.

Workshops on Introduction to Composites, Composites Machining, Machine Tools, Product Development, Composites Processes and areas of related interest are conducted on quarterly basis. Workshop calendar is updated frequently. An example workshop conducted in Summer 2020 is provided in this link.

Composites for Automotive, Truck and Mass Transit

Composites for Automotive, Truck and Mass Transit

This technical book provides a comprehensive explanation of how advanced composite materials, including FRPs, reinforced thermoplastics, carbon-based composites and many others are designed, processed and utilized in exterior, interior, under-the-hood, structural, semi-structural and non-structural components in passenger cars, performance cars, trucks, motorbikes, and mass transit vehicles.

Practical Composites for Schools, Colleges and Hobbyists

Practical Composites for Schools, Colleges and Hobbyists

The book is intended for educators, middle and high schools, community colleges, engineering students, hobbyists and anyone interested in space-age materials for daily use.

Learn More

The Futures is Advanced Plastics and Composites

The Futures is Advanced Plastics and Composites

This teaching module is aimed at providing a basic understanding of polymer matrix fiber reinforced composites, terminology and basic types of fibers and matrices used, advantages, applications, manufacturing techniques, sandwich, ceramic and metal matrix composites.

Learn More

JComp B: Composites B : Engineering (An Elsevier Journal)

Check out the leading journal in Composites – Composites Part B : Engineering

2021 Impact factor 9.078

Media coverage of FCMF accomplishments & activities with collaborators

The FCMF team activities are continually featured in the media. Here are some recent compilations.

Traditional vs. Sustainable manufacturing

Komal Kooduvalli, former (2017-2019) Research Supervisor at FCMF and Hayley Coughlin, IACMI intern (former, 2018) working at FCMF, compiled a few slides relating to Sustainability within the context of the composites and materials industry.

Sustainable vs. Traditional Manufacturing