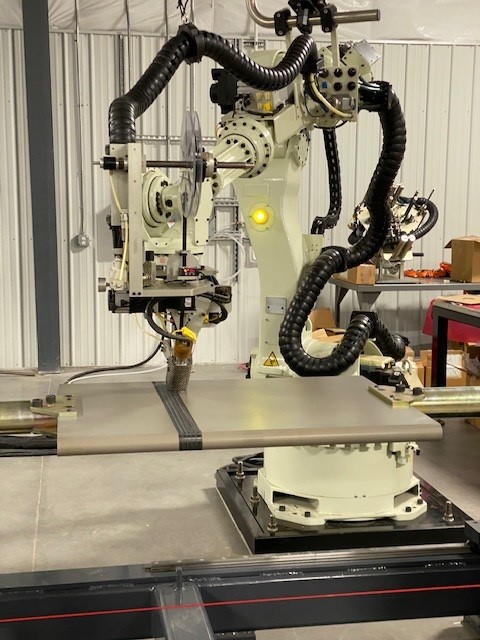

The Institute for Advanced Composites Manufacturing Innovation – University of Tennessee (IACMI-UT) has commissioned an Automated Tape Placement (ATP) system at its Knoxville facility, significantly enhancing integrated manufacturing capabilities in East Tennessee.

This state-of-the-art ATP system features:

-

A Trelleborg Automated Dynamics 6-axis Kawasaki Model ZZX130LD CNC Robot

-

Dual-material feeding system for both thermoplastic tape and thermoset tow-pregs

-

Advanced compaction roller head technology

-

Flexible mandrel accommodation (cylindrical, flat, asymmetrical)

-

CAD interface compatibility with additive manufactured mandrels

The system processes advanced materials including:

-

Carbon/Polypropylene (C/PP)

-

Glass/Polypropylene (G/PP)

-

Carbon/Polyether ether ketone (C/PEEK)

-

Carbon/Epoxy (C/Epoxy) composites

Applications & Impact:

The ATP system will support:

-

Aerospace component manufacturing

-

Defense applications

-

High-performance automotive parts

-

Infrastructure and power transmission solutions

Contact:

Dr. Uday Vaidya: uvaidya@iacmi.org